location > Home / Product / Aluminum rod

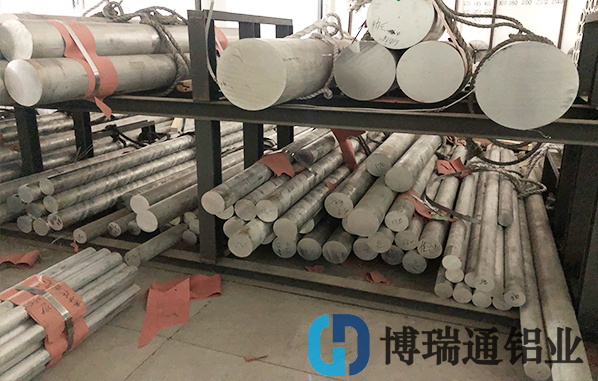

Category: aluminum rod

Brand: 7075

Form:T6、T651

Click:1507

Make to order

Original warranty

Brand certification

Timely delivery

7075 aluminum bar is a cold-treated forging alloy with high strength, far superior to mild steel.The 7075 is one of the strongest alloys commercially available.It can reach very high strength properties when subjected to heat treatment.7075 aluminum bar generally add a small amount of copper, chromium and other alloys, the series of 7075-t651 aluminum alloy is particularly top grade, known as the most excellent products in aluminum alloy, high strength, far better than any soft steel.The alloy also has good mechanical properties and anodic reaction.

7075 aluminum bar mainly contains zinc element.Also belong to the aviation series, is copper alloy, aluminum and magnesium zinc is heat treatable alloys, belongs to hard aluminum alloy, have good wear resistance. 7075 aluminum rods is by eliminating stress, not deformation, warping after processing. All super ultra thick 7075 aluminum rods by ultrasonic detection, can guarantee without sand holes, impurities. 7075 aluminum rods of high thermal conductivity, can shorten the molding time, improve work efficiency.The main characteristic is the hardness of 7075 is high hardness, high strength aluminum alloy, often used in the manufacture of aircraft structure and futures.It requires high strength, corrosion resistance of high stress structural parts, mold manufacturing.

Typical USES:

7075 aluminum bar is mainly used for the manufacture of aircraft structures and other high-stress structures requiring high strength and corrosion resistance, such as aircraft, lower wing facing panels, truss bars, etc.Good plasticity after solid solution treatment, good heat treatment strengthening effect, good strength below 150 degrees, and has particularly good low temperature strength, poor welding performance, a tendency to stress corrosion cracking.Also widely used in mold processing, mechanical equipment, fixtures, aerospace industry, blow molding (bottle) mold, ultrasonic plastic welding mold, golf head, shoe mold, paper mold, foam molding mold, dewaxing mold, mechanical equipment, used in the production of high-end aluminum alloy bicycle frame.In 2014, it will be used for the first time as the body material of the smartphone OPPO N3.

| alloy designation | 硅Si | 铁Fe | 铜Cu | 锰Mn | 镁Mg | 铬Cr | 锌Zn | 钛Ti | 锆Zr | other | AL | ||

| mark | 0.4 | 0.5 | 1.20-2.00 | 0.3 | 2.1-2.9 | 0.18-2.8 | 5.10-6.10 | 0.2 | - | each | total | ||

| 7075 | - | 0.05 | 0.15 | margin | |||||||||

| Aluluminium alloy brand | strength of extension/Mpa | yield strength/Mpa | elongation/% | hardness |

| 7075-T6/T651 | 540 | 460 | 8 | 150 |