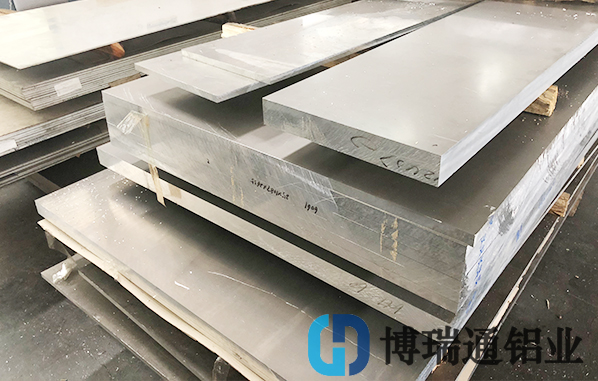

We all know that the utilization rate of 6061 aluminum plate is higher, mainly because its strength, hardness and tensile properties are relatively moderate, then in the production and processing of 6061 aluminum plate, we generally use molds. What is the impact of molds on the production of 6061 aluminum plate?Next 6061 aluminum plate manufacturers to detail.

1, first of all, the design of the mold should be adjusted according to the performance of 6061 aluminum plate, and its stiffness and strength should be designed well, mainly in order to reduce the elastic deformation of the mold when it is under pressure.

2. Secondly, when designing the mold, the error should be reduced and the interior should be smooth. Otherwise, it will cause friction on the surface of the 6061 aluminum plate, leading to uneven surface of the 6061 aluminum plate.

3, and the mold before use to go through nitriding treatment, mainly in order to avoid the emergence of the problem of sticking aluminum.

The influence of the mold on the production of 6061 aluminum plate is introduced here. If you want to know about the price of 6061 aluminum plate, you can call us to consult.