Has die design are used digital design tools and then carry on the processing, ultrasonic mould design which has been widely applied at present, we all know that 6061 aluminum plate can be used as mould material, actually 7075 aluminum plate can also be used in the mold material, that we are using 7075 aluminum mold may be damaged, now what are the main reasons cause 7075 aluminum mold damage?

First, ultrasonic 7075 aluminum mold design is not reasonable, production fails to reach the frequency is not careful selection of plastic, so use in the process of ultrasonic energy won't be completely released, but most remain in mold ultrasonic 7075 aluminum, using 7075 aluminum die over time there will be a welding not firm, is then followed by mold mold hot crack, to solve this problem, we must first select manufacturers more professional ultrasonic mould, success and failure is certainly occupy more than half, if have have in manufacturing master design to production, if there are multiple times, make the mould maintenance frequency,To be at your best.

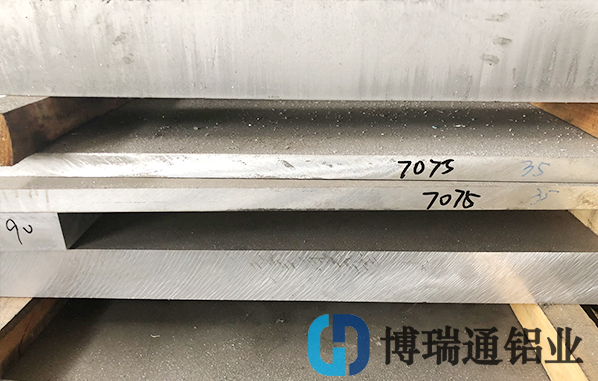

Secondly, 7075 aluminum plate is used to select the material of the mold. 7075 aluminum plate is wear-resistant, corrosion-resistant and has good mechanical processing performance. Its hardness is slightly higher than that of other aluminum alloys in China.

This is the reason for the damage of 7075 aluminum plate mold. If you need to know more about 7075 aluminum plate, please contact us.