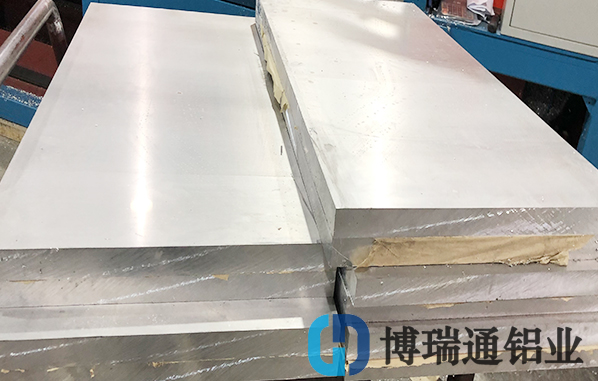

2A12 aluminum plate is a better strengthened aluminum alloy, which can be used in precision machinery. When the parts of 2A12 aluminum plate shell are processed by NUMERICAL control of the inner surface after heat treatment, longitudinal cracks on the inner surface of the parts are found after inspection.Then, 2A12 aluminum plate manufacturers will give you an analysis of the specific reasons and solutions.

The 2A12 aluminum enclosure is analyzed by the macroscopic, microscopic inner surface of part of the crack, and the treatment component therein, in order to identify the cause of the fault. Finally, improvement Suggestions are proposed.

Through the study of the chemical elements out of the fracture, it is found that the chemical elements are in line with the national standards, so that the possibility of cracking on the inner surface of parts caused by raw materials can be eliminated.The inner surface of the defective component may crack due to serious metallurgical defects.

Next, the processing technology is studied and analyzed. The processing technology of 2A12 aluminum plate shell parts is as follows: blanking → center hole of the car → heat treatment → interior hole. Before heat treatment, the wall thickness of the parts reaches 92.5mm.The analysis shows that the crack between the inner wall of 2A12 aluminum plate shell is caused by the pipe wall thickness and the heat treatment technology is not sufficient.

According to the actual situation of further optimizing heat treatment process of 2A12 aluminum plate shell part, quenching and artificial aging heat treatment.The well furnace was heated to 495±5℃ for 180-210min, and water cooled. No overfiring was found, and the accumulation of grain boundary along the phase was significantly improved.It is proved that the initial site of partial surface crack is not sufficient due to heat.

According to the previous cutting speed and cutting amount, different stresses at the tip of 2A12 aluminum plate are mainly concentrated at the grain boundary intensification phase, and the crack will expand more rapidly along the direction of the intensification phase zoned distribution.

2A12 Aluminum plate inner surface machining axial crack occurs during heat treatment transfer.By scanning the cracks, it was found that the heat treatment at the center of the parts was not sufficient, and the cutting speed and cutting quantity were too large during the machining process, which were the main reasons for the formation of cracks.

In order to avoid the inner wall crack defects of 2A12 aluminum plate shell parts in the process of processing, it is suggested to increase the processing size of the center hole before heat treatment and accelerate the cooling speed of the parts in the process of heat treatment, so as to promote the complete transformation of the tissue.

2A12 aluminum plate shell parts heat treatment cracks and solutions are introduced here, if you need 2A12 aluminum plate can contact us.