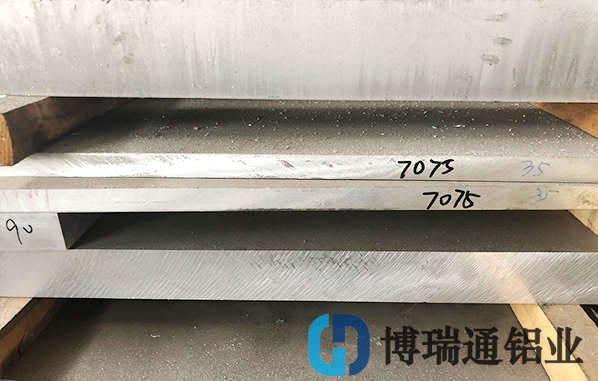

When the 7075 aluminum plate casting block is made from milk to the thickness of the plate is about 180mm, the end part of the plate is prone to warping in the upward direction. Next, 7075 aluminum plate manufacturer will give you an analysis of the causes and solutions for the warping of 7075 aluminum plate.

The main reasons are as follows:

1. The diameter difference or temperature difference between the upper and lower working rollers is too large.

2. The gap between the rolling bearing box and the working roll upper and lower moving slide is too large.

3. The chute clearance at the joint between the shaft neck and universal shaft is too large.

4. Improper operation during heating and hot rolling.

Methods to reduce the warping of 7075 aluminum plate:

Because the internal stress is kept in the 7075 aluminum plate, when the number of parts is large, rough machining must be carried out, so rough machining is essential.In a non-deforming natural state, in which there is a warping and is fixed to withstand the cutting force, one side is completed and cut to reduce the maximum cutting force.Flip the other side.So depending on how much stress is inside you get warped, and you get flatness and parallelism.

The 7075 aluminum plate warps and needs leveling.Leveling by heat leveling.The main reason is that it will not damage the surface, at the same time, good dimensional stability.

The above are the causes and solutions for 7075 aluminum plate warping. If you need 7075 aluminum plate, please contact us.