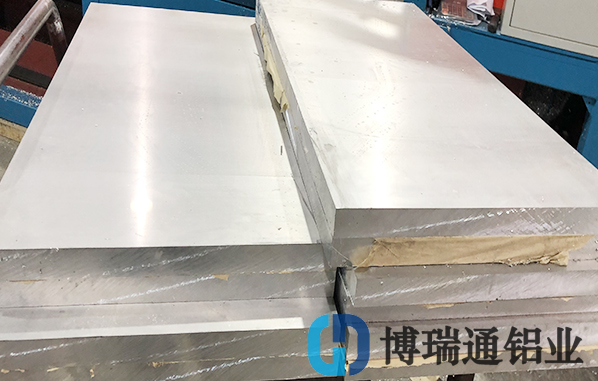

2A12 aluminum plate is generally used in the machining of more precise mechanical parts, and the accuracy of the size is required to be better. Then, under what circumstances will the accuracy become worse?Next 2A12 aluminum plate manufacturers to give you an analysis.

First of all, the machining accuracy of 2A12 aluminum plate parts is poor. During installation, the dynamic error between shafts is not adjusted well, or the shaft transmission chain changes due to wear, which will affect the precision of 2A12 aluminum plate parts.

In addition, the overshoot of another machine tool during operation will also affect the machining accuracy of 2A12 aluminum plate, which may be mainly because the acceleration and deceleration development time is too short. Of course, it is also likely to occur because the link between the lead screw and the servo control motor can be loosened.The accuracy of aluminum 2A12 precision parts may be affected by the fact that the roundness tolerance of the two axes is not circular due to mechanical deformation through axial adjustment, or the lead screw axis does not play a compensating positioning axis movement.

The 2A12 aluminum plate processing of the previous process cannot directly affect the next process, interspersed with the production and processing of general purpose machine tools should also improve the comprehensive analysis consideration.In the same location, same knife or clamp connection processing step, in order to reduce repeated positioning, change the number of knives and move the platen.

The above is the introduction of the poor accuracy of 2A12 aluminum plate. If you need 2A12 aluminum plate, please contact us.