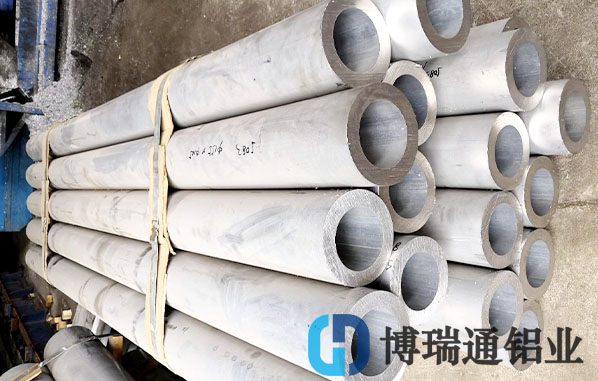

2A12 aluminum tube in the use, sometimes the surface is very bright, that is because did the polishing treatment, the next 2A12 aluminum tube manufacturer will introduce to you, 2A12 aluminum tube polishing process.

Polishing is the use of mechanical, chemical or electrochemical operations to reduce the surface roughness of 2A12 aluminum tube, to obtain a bright, flat surface.It is the use of polishing treatment tools and abrasive particles or other project polishing media through the surface of the 2A12 aluminum tube modification and processing polishing.

Tend to use when polishing the polishing wheel, polishing, high speed polishing wheels (circumferential velocity in more than 20 m/s) pressure to the 2 a12 aluminium pipes pieces, between the abrasive on the surface of the 2 a12 aluminium pipes for rolling and micro cutting, so that they can get a brightness of the surface of the processed products, surface roughness requirements general ability of Ra0.63 ~ 0.01 microns.When a large number of steel balls, lime and abrasive canal-shaped tilt drum, drum rotation, ball and abrasive random collision drum roll to achieve convex front surface and remove surface roughness reduction, can be about 0.01mm removal margin.When the ball is finely ground and the pelt is in the barrel, it is continuously rotated to load for several hours to obtain a bright shiny surface.

The above is about the polishing process of 2A12 aluminum tube, if you want to know the price of 2A12 aluminum tube, you can consult us.