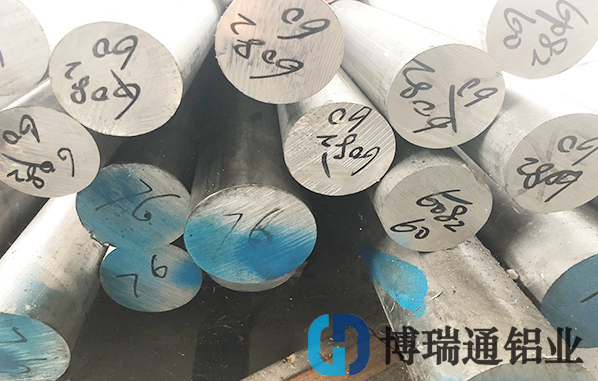

The 6082 aluminum bar is usually produced by extrusion. What should be paid attention to when producing?Next 6082 aluminum bar manufacturers to give you a brief introduction.

(1) Heating method of 6082 aluminum bar

1. 6082 aluminum bar heating using frequency induction heating, its thermal characteristics are as follows:

2. Short heating treatment time, reaching about 500℃ within 3 minutes;

3. The extrusion time temperature control system has high precision and the error does not exceed ±3℃.

4 If the resistance furnace is heated slowly, Mg2Si phase will be precipitated, which will affect the reinforcement effect.

(2) Aluminum extrusion

Changed the following several factors, 6082 aluminum bar extrusion process will be relatively reasonable.

1. 6082 aluminum bar has certain deformation resistance, so the casting bar temperature control should be an upper limit (480-500℃);

2. The mold temperature of aluminum extrusion should be high;

3, in order to prevent shrinkage or bubbles, oxides, impurities, etc., the pressure should be kept longer;

4. Complete solid solution of Mg2Si alloy mainly through strengthening phase to ensure quenching temperature above 500℃, extrusion time temperature of solid structure profiles should be controlled within 500-530℃;

5, 6082 aluminum bar quenching high sensitivity.The alloy contains Mn, which needs quenching cooling strength and cooling speed. It must be quenched by water, and its temperature is quickly lower than 50℃.

6, 6082 aluminum bar sawing, the frame should protect us a certain time interval, do not discharge living too close.

The above is the attention of 6082 aluminum bar extrusion production. If you need to consult the price of 6082 aluminum bar, please contact us.