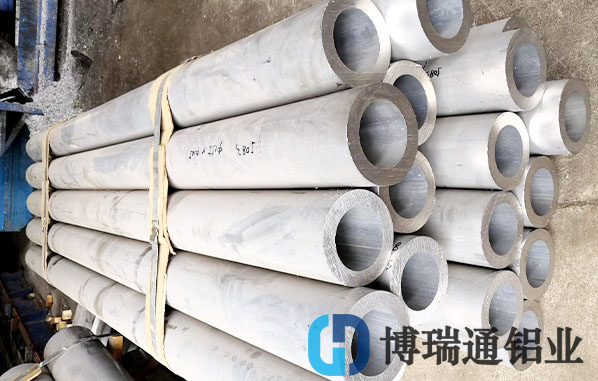

2A12 aluminum tube production and processing often use perforated extrusion method, 2A12 aluminum tube in the production to ensure its strength and hardness and flattening test, next 2A12 aluminum tube manufacturers to tell you, the production process of 2A12 aluminum tube.

First of all to set the aging furnace temperature, set the table temperature according to the actual working temperature to set.In the process of production development to carefully treat, master each step.

2A12 Aluminum tube characteristics: high strength, certain heat resistance, can be used for 150 degree of working part.The temperature is obviously higher than 125 degrees, the forming system performance in thermal state, annealing and new quenching state is relatively good, the learning effect of heat treatment intensification is significant, but the design of heat treatment process requires students to be strict.Corrosion resistance is general, but can be coated with pure aluminum;It is easy to crack when welding, special welding technology is needed, and riveting can also be used.Widely used in aircraft structure, rivets, truck wheels, propeller parts and other structural parts.

The above is about the production process of 2A12 aluminum tube. If you need to consult the price of 2A12 aluminum tube, please contact us.