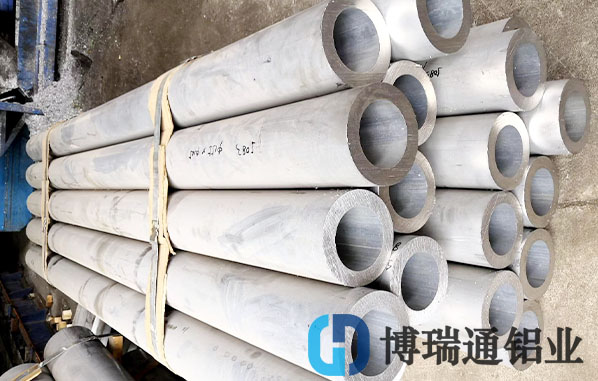

The 2A12 aluminum tube is commonly used in the aerospace field, so it has a high quality requirement. How about when the customer purchases the 2A12 aluminum tube, how to judge the quality?As 2A12 aluminum tube manufacturers to recommend a method to everyone, that is 2A12 aluminum tube can be detected by flaw detection to detect the quality.

1. The s-wave reflection method is adopted to conduct automatic inspection when the probe and the 2A12 aluminum tube move relative to each other. Only the special large diameter 2A12 aluminum tube can be inspected manually.

2. During longitudinal inspection, sound beam is transmitted along the circumferential direction inside the 2A12 aluminum tube wall;During the transverse inspection, the acoustic beam is propagated along the axial direction in the 2A12 aluminum tube wall.Provided that both longitudinal and transverse tests are carried out in opposite directions on the 2A12 aluminium tube.

3. In the absence of clear inspection requirements, longitudinal and transverse defects can only be tested in one direction of the 2A12 aluminum tube.

4. Good materials on the surface of 2A12 aluminum tubes shall be used for automatic or manual inspection.

The quality of 2A12 aluminum tube can be detected by flaw detection method is introduced here, if you need to consult the price of 2A12 aluminum tube can contact us.