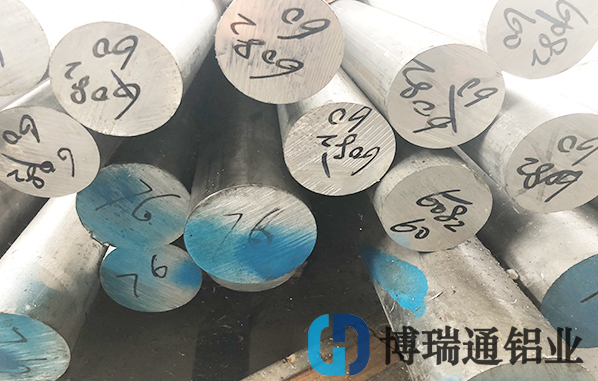

The 6082 aluminum bar is produced by extrusion, and generally needs casting and oxidation treatment. Today the 6082 aluminum bar manufacturer would like to briefly talk about the casting and oxidation process of 6082 aluminum bar.

The casting process of 6082 aluminum bar mainly includes:

The raw materials are first matched with 6082 aluminum bar alloy elements, then melted, and the material box and waste gas are removed by degassing, etc.Finally, through a certain process, the molten aluminum is made into various types of 6082 aluminum bar. This is the casting process of 6082 aluminum bar.

The oxidation process of 6082 aluminum bar is mainly as follows:

Adopt the method of adding surfactant oil, the use of surfactant unique physical and chemical properties of lower surface tension, the emulsification, solubilization and foaming effect, as well as to the base, their good chemical stability, such as the hard water can improve the effect of degreasing and cleaning and make alkaline surface to form a layer of foam layer, prevent the alkali fog escape, reduce pollution, and improve operating conditions.This method is mainly simple and good operation, and small pollution to the environment, so currently used more.

The casting and oxidation process of 6082 aluminum bar is introduced here. If you need to know the price of 6082 aluminum bar, please contact us.