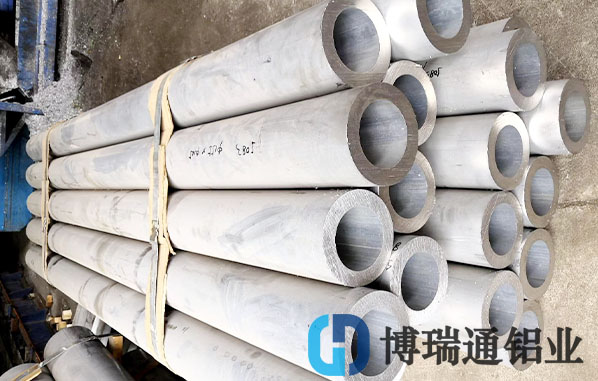

I don't know if you have found that unqualified products may appear in the production of 2A12 aluminum tube. Sometimes, the mold problem leads to differences in shape and size. Next, 2A12 aluminum manufacturer tube will introduce to you the influence of mold on the production of 2A12 aluminum tube.

I. Bad influence of seam welding:

2A12 aluminum pipe is extruded by plane split die, which is difficult in profile production.The metal is welded in two parts, so there is a welding line in the 2A12 aluminum tube.

There are two reasons for the occurrence of a gap: first, the diverter hole and the welding chamber are narrow, the metal supply is insufficient, the product is not well welded and the mold hole flows out, leading to the existence of welding gap in biological products enterprises;Second, excessive lubrication and adverse effect of lubrication, resulting in poor 2A12 aluminum tube.

2. Cause analysis of concave and convex cambered surface of 2A12 aluminum tube wall

1. Important reasons for the concave bow surface under the wall of 2A12 aluminum tube: the working belt of 2A12 aluminum tube core is lower than that of the working belt of the bottom mould hole, which is caused by the working belt of the mould core is too short.

2. Reasons for the outer wall of 2A12 aluminum tube: the mold has been used for too long, the working belt of the mold core is seriously worn, grooves appear, friction resistance increases, and the metal flows slowly, resulting in the convex hollow section wall.

The influence of mould on the production of 2A12 aluminum tube is introduced here. If you need to know the price of 2A12 aluminum tube, please contact us.