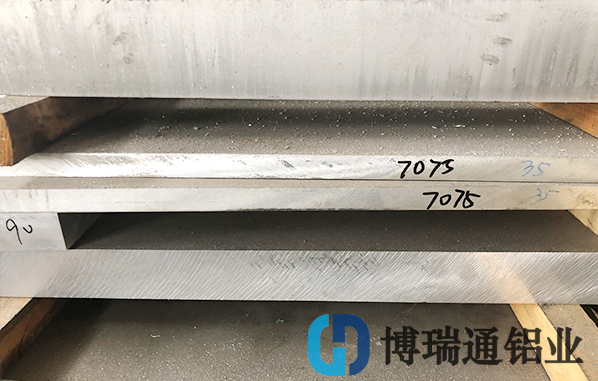

We all know that the hardness of 7075 aluminum plate is higher than that of aluminum alloy materials. The production mode of 7075 aluminum plate is different, and its performance is also different. Next, 7075 aluminum plate manufacturer will introduce to you the performance difference between calendering and extrusion of 7075 aluminum plate.

The hardness and strength of 7075 aluminum plate calendering is higher than that of 7075 aluminum plate extrusion. There are more updates of 7075 aluminum plate calendering, and the deformation of the material from the raw material to the finished aluminum plate is greater. 7 and after the pre-stretching treatment, the internal stress is eliminated, so that the 7075 aluminum plate processing is not easy to deformation.7075 aluminum plate extrusion process is relatively simple, its accuracy, hardness, material performance is slightly less than the rolling 7075 aluminum plate.

The performance of 7075 aluminum plate calendering is better than that of extruded 7075 aluminum plate, and the internal tissue distribution is uniform. It can weld the loose, shrinkage holes and cracks inside the ingot, and the density and hardness of the material are better.

The good performance of 7075 aluminum plate makes it favored by more industries, widely used in aerospace, mold, auto parts, rail transit and other industries.

The performance difference between calendering and extrusion of 7075 aluminum plate is introduced here. If you need to consult the price of 7075 aluminum plate, you can contact us.