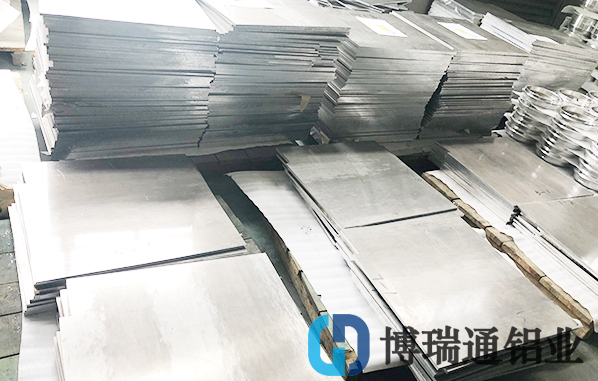

2024 aluminum plate is often used in mechanical parts, and the use of mostly thick plate, but in use may find that 2024 aluminum plate has a brittle situation, that is what causes it?Next 2024 aluminum plate manufacturers to give you a secret.

2024 aluminum brittle insufficient pressure may be the cause of the die and insufficient pressure touching someone might be due to mold compression than the impact of the length of the straight segment, peace due to shunt bar 2024 aluminum plate, which is usually caused by poor convergence performance degradation, should be appropriately increased muscle and outside surface, reinforcement and reinforced the confluence of the length, or increase the compression ratios, the change of the die head pressure can be adjusted by changing the die head straight length material flow resistance.

At the stage of die design, different compression ratios should be designed to control the extrusion pressure, and the size of melt pressure can be changed by changing the formula, adjusting the extrusion parameters and increasing the porous plate.The performance of 2024 aluminum plate will also be affected by the cooling rate of the mold and the cooling water temperature. The role of cooling water is to cool the large molecular chain of 2024 aluminum plate stretching and finalize the design in time to achieve the purpose of use.

2024 aluminum plate brittle reason is introduced here, if you need to understand the price of 2024 aluminum plate can contact us.