Under normal circumstances, 7075 aluminum plate is generally cut by sawing machine, but some customers will choose laser cutting, because the laser cutting accuracy is better, the section is smooth, but sometimes 7075 aluminum plate manufacturers found that the use of laser cutting will also appear burr, then what is the reason for this?

1, first of all may be 7075 aluminum plate in the laser cutting machine power is not enough, then this time to check whether the laser cutting machine is abnormal, such as abnormal to timely maintenance, if there is no abnormal that may be the output value of the problem, it needs to adjust the parameters in time.

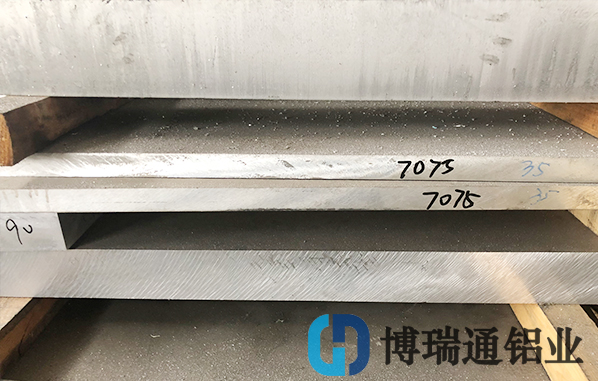

2. It may be the problem of 7075 aluminum plate. If the machine runs normally, the value is no problem, and there is a burr in cutting, it may be the quality of 7075 aluminum plate.

3. In addition, if the 7075 aluminum plate appears burr, it may also be a problem of operation. It is necessary to conduct formal training for the operators so that they can operate the equipment skillfully.

The above is not only about the reason of 7075 aluminum plate laser cutting burr, there may be a lot of small problems, small edition is not a detailed, if you want to consult the price of 7075 aluminum plate, you can contact us.