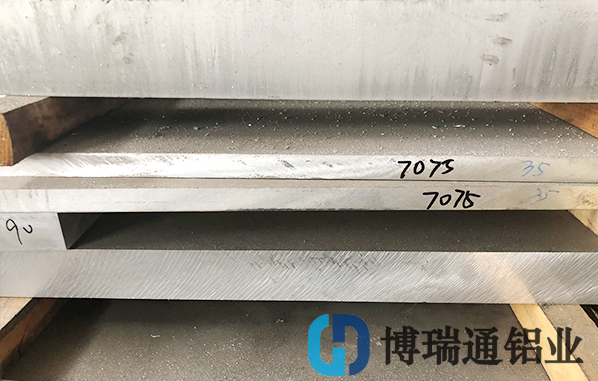

7075 aluminum plate need to be cut before use, then sometimes the surface of 7075 aluminum plate after cutting is rough, then what is the reason for this?Next 7075 aluminum plate manufacturers give you uncovering the secret.

When the thickness of the excited disc is greater than 2 mm, the surface gravity distribution is not uniform and the thickness varies greatly.If you are not fully aware of cutting the aluminum plate, it is likely that the influence will lead to student errors.The surface gravity of traditional laser shears should be controlled effectively.

Whether the enterprise continuous laser shielding machine or need another is a pulse laser shielding machine, cutting 7075 aluminum plate will have a clear display of a picture.The higher the difference frequency, the thinner the edge and the greater the surface gravity.

In general, in this case, the thickness of the small 7075 aluminum plate parts than the thickness of the large 7075 aluminum plate parts cutting is relatively simple.When the thickness is less than 3mm, the surface roughness is smaller.Laser cutting plate 7075 aluminum plate is generally based on surface gravity and RA having the following problems, more practical and easier to achieve control.

This is the reason why the surface of 7075 aluminum plate is rough after cutting. If you want to consult the price of 7075 aluminum plate, you can contact us.