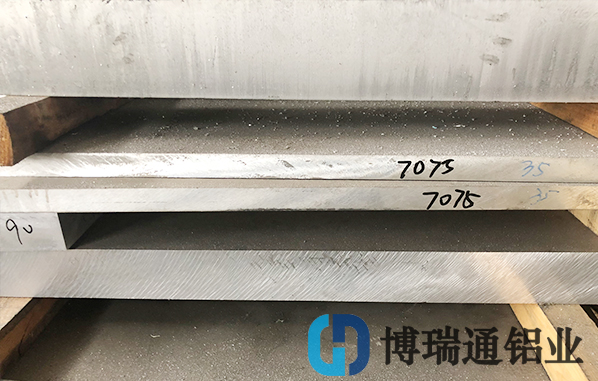

7075 aluminum plate will be stretched after production and processing, mainly in order to remove the internal stress to obtain better performance, but 7075 aluminum plate will encounter some defects when stretching, and the next 7075 aluminum plate manufacturers will talk about it specifically.

1. Improper cleaning of residual stress

Usually due to the uneven clamping mouth before stretching, the local fluctuation of 7075 aluminum alloy plate is too large, and the limited stretching amount is not enough to remove the residual stress, resulting in new uneven stress distribution.The sawing operation is too small for both ends and sides of 7075 aluminum alloy.Therefore, maintaining a good shape of hot rolling, standard drawing process, etc., is an important working condition of drawing.

2. Stretch process interrupt sheet

, in the process of 7075 aluminum plate tensile pieces usually melt quality is poor, internal slag, porosity, processing distribution unreasonable result in hot rolling passes, uneven deformation of 7075 aluminum plate surface and core, core have serious as-cast transition interlining, may be due to the edge of the hot rolled steel plate defects, such as cracking, cracking, slag inclusion, lead to stretch.

3. Stretch slip line

The tensile slip line is due to the excessive amount of drawing exercise and the excessive amount of pressing work in the leveling process before drawing, and the repeated use of quenching, stretching and quenching.

7075 aluminum plate in the tensile time will encounter some defects mentioned here, want to consult the price of 7075 aluminum plate can contact us.