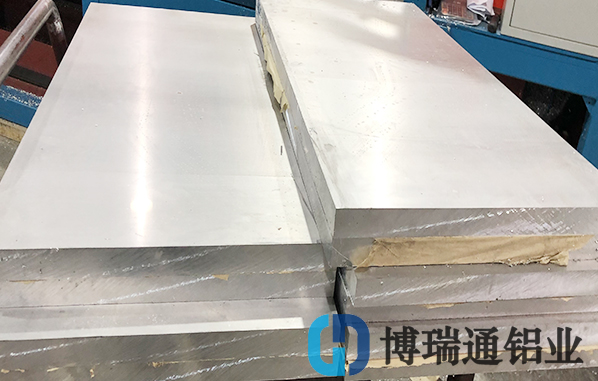

2A12 aluminum plate in use is generally needed to be cut, mainly in order to meet the use of the size of the customer, then what is the impact of cutting surface roughness when cutting?The following by the 2A12 aluminum plate manufacturers to detail.

1. Roughness is an important measure of 2 A12 Aluminu, which is helpful for enterprises to improve the roughness of their products and reduce the surface adhesion between students caused by annealable damage caused by trade friction.

2. Divide the shape of the cutting surface into two different parts.The upper surface is smooth and the surface is flat, the cutting stripe structure is neat and compact, and the roughness value is small.The lower part is messy, the surface is not smooth, and the roughness value is large.The upper structure has the characteristics of laser beam direct effect, and the lower part has the characteristics of Chinese liquid metal erosion.

3. The main difference is that the cutting fringe of the surface cut by the pulse laser is related to the pulse signal frequency.The higher the cutting frequency, the finer the stripes, the greater the surface roughness of the hardware system accessories.The density and surface roughness of the upper cutting fringe are mainly related to the development of actual cutting speed.

The influence of 2A12 aluminum plate cutting roughness is mentioned here. If you want to consult the price of 2A12 aluminum plate, you can contact us.