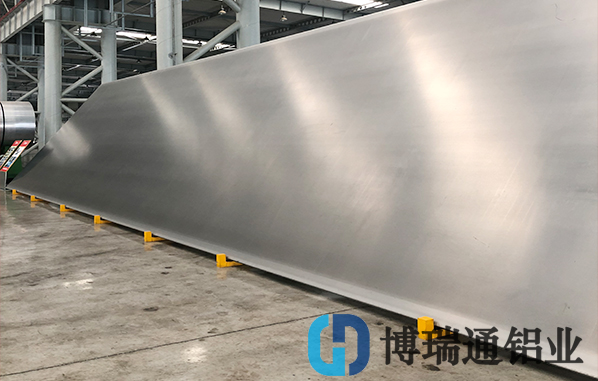

5083 aluminum plate is our common aluminum plate material, often used in the transportation industry, better performance, stamping process requirements, then the next small series to give you a specific introduction, 5083 aluminum plate forming process and mold requirements.

I. key points of stamping forming process

1, the surface lubrication of 5083 aluminum plate material is very important for forming, currently 5052 aluminum plate is generally used dry lubrication, the lubrication process relative to grease lubrication can make 5083 aluminum plate have better forming performance.

2, the forming die to ensure good forming process, the die holder ring fitting rate must reach more than 85%, and the blank holder ring and mold surface need to ensure smooth and clean, conditions allow the case of chrome plating.

3, 5083 aluminum sheet forming equipment for the blank holder force output control also has higher requirements.If it is a single dynamic press, do not choose air cushion forming equipment, should use pressure control more stable CNC hydraulic pad or servo motor control pad.

Two, 5083 aluminum sheet stamping forming matters needing attention

1. Compared with the steel plate material, 5083 aluminum plate has its special requirements for the cutting and punching process mold. Due to the soft performance of 5083 aluminum plate, the punching and punching die gap is smaller than the ordinary mold, and the single-side gap should be controlled at about 3% ~ 4% material thickness.

2. The cutting edge of the stamping die shall have a high hardness, which must be above 60HRC.

3. The guidance of punching die shall be fully inspected every six months.

About 5083 aluminum sheet forming process points and matters needing attention are introduced here, if you need 5083 aluminum sheet can contact us.