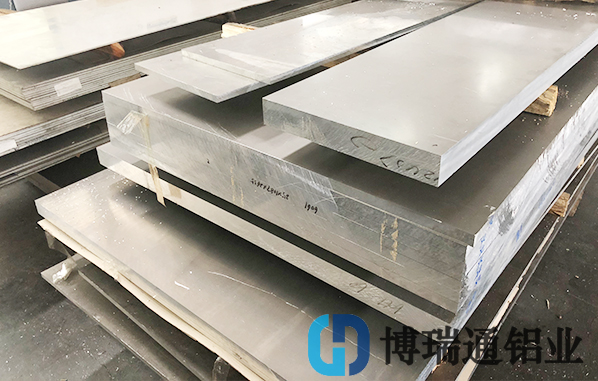

At present, with the increasing use of aluminum plate, many customers have requirements on the surface of 6061 aluminum plate. There are many factors affecting the surface of 6061 aluminum plate, such as the roughness of the roller surface, temperature and aluminum adhesion, etc. How can we control the surface roughness of 6061 aluminum plate?

Surface condition of rolls and 6061 aluminum sheet rolled pieces.The oil film thickness in the rolling deformation zone of 6061 aluminum plate is not only subject to the fluid pressure, the rolling deformation zone, the contact surface roughness, the larger contact area, the smaller film thickness and the larger friction coefficient, but the film strength is large enough to improve the surface quality after the rolling of 6061 aluminum plate.When the speed increases and the acting speed increases, the effect will gradually reduce the surface roughness. Under the condition of fluid lubrication, the roughness effect will completely disappear.However, the roughness will affect the bite of the 6061 aluminum plate rolling piece, so it is necessary to control the roughness of the contact surface, so as to improve the performance of the lubrication system.The roughness of the work roller is controlled by 50 constant m-55 constant m.

How to control the surface roughness of 6061 aluminum plate is introduced here, in fact, this is just a small summary of the experience, if you need to know more about the 6061 aluminum plate information can be added to our WeChat for more in-depth communication.