7075 aluminum plate parts in the process of deformation, there are many reasons, in the actual operation, the operation method is also very important, the next small series in view of this problem to give you a specific analysis.

1, the processing of 7075 aluminum plate parts with large spare capacity, need to have better heat dissipation technical conditions, to avoid the main concentration of heat, processing, it is appropriate to adopt symmetrical processing.When a 90 mm thick 7075 aluminum plate needs to be processed to 60 mm, if the milling side immediately after milling the other side, a processing to the final size, the flatness of 5 mm;If the feed is processed symmetrically and each side is processed twice to the final size, the flatness of 0.3 mm can be guaranteed.

2. Multiple cavities, such as the 7075 aluminum part, should not be treated with a sequence processing method for a cavity in the mold cavity, so it is easy to cause discontinuous deformation of parts.Adopt layering machining, and increase machining to all the cavities, so that the parts can be stressed evenly and the deformation can be reduced.

3, by changing the cutting force, cutting heat, in order to reduce the amount of cutting.If the machining allowance is too large, the cutter cutting force is too large, will not only make 7075 aluminum plate parts deformation, but also affect the rigidity of the machine tool spindle, reduce the durability of the tool.If you reduce the number of cutting tools on your back, you will make your production much less efficient.CNC machining is a high speed milling process that needs to be overcome.At the same time, reduce the amount of cutting tool behind, as long as the corresponding increase in the raw material, increase the rotation speed of the machine, cutting force can be reduced, while ensuring the efficiency of the processing.

4. There are requirements on the knife running order.Rough machining is to improve the efficiency of machining, cutting rate is high, generally can be used reverse milling.In short time, the excess material was cut off quickly to form the geometric outline required for finishing.Precision machining is high precision and high quality, most of the use of shun milling, shun milling cutter tooth cutting thickness is gradually decreasing, greatly reduce the degree of hardening, while reducing the deformation of parts.

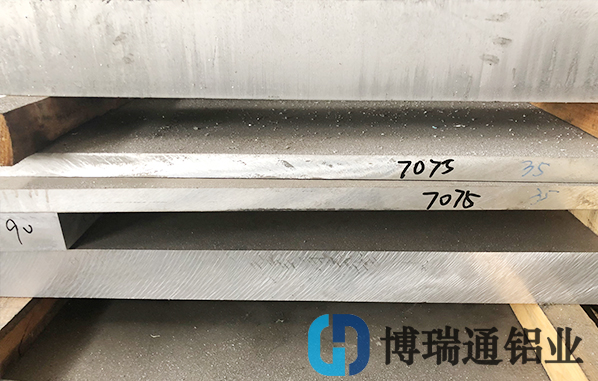

The solution to the deformation of 7075 aluminum plate parts in the process of processing is introduced here, if you need 7075 aluminum plate can contact us.