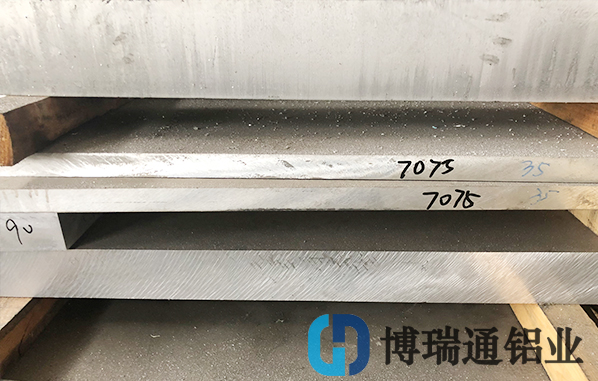

7075 aluminum plate is high strength and high hardness aluminum alloy material, currently mainly used in the field of aerospace, that 7075 aluminum plate in the processing is actually after heat treatment, but in the heat treatment may occur hot brittleness, hot brittleness refers to the alloy in the state of high temperature to form heat cracks.Next 7075 aluminum plate manufacturers to introduce you, 7075 aluminum plate hot brittleness.

Thermal crack formation strength theory, the alloy tends to form a thermal cracking and solid linear shrinkage liquid within the plastic range depending on the effective crystal size, and no thermal crack will occur at the elongation rate of no more than 0.3%.For 7075 aluminum plates, the minimum relative elongation of the solid liquid is in the range of 0.1% to 0.5%, based on the alloy only up to 0.5% to 0.7% with only a small relative elongation of al-si.The possibility of thermal crack exists in 7075 aluminum plate.

The lower part of the crystallized portion, these alloys retain only a small amount of liquid, and as the temperature decreases further, the amount of these phase changes is very weak.The crystallization characteristic makes the relative elongation of the alloy decrease, and it can be kept low in a certain temperature range.In the multi-component alloy, the crystallization of the binary eutectic layer rapidly reduces the width between the gin and the distribution along the thickness, resulting in the relative elongation of the temperature interval of the alloy almost jumping up and down.In casting process, it is impossible to avoid the brittleness of solid and liquid.This is 7075 aluminum plate hot brittleness of the fundamental reason.

The above is about the hot brittleness of 7075 aluminum plate, if you want to know more about the content of 7075 aluminum plate can contact us.