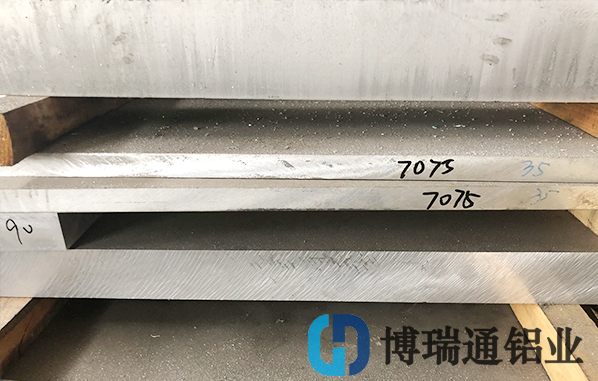

7075 aluminum plate is known as high-strength and high-hardness aluminum plate, which is often used in precision machinery. Next, 7075 aluminum plate manufacturer will introduce to you the change of microstructure and properties of 7075 aluminum plate in the process of thermal deformation.

At high temperature, 7075 aluminum plate has high plasticity and low resistance, which will aggravate the atomic diffusion process, accompanied by complete recrystallization, which is beneficial to improve the tissue.The thermal deformation can change the as-cast structure of 7075 aluminum plate and make favorable changes in as-cast structure when the three-way compressive stress is dominant.

1. Thermal deformation is usually accomplished by repeated deformation through multiple passes.Due to the simultaneous hardening and softening process, deformation and coarse columnar grain fracture occurred in the enterprise, the repeated deformation of the tissue material became more uniform and fine equiaxed grain.Also, tiny crack problems can heal.

2. Due to the effect of hydrostatic pressure in the stress state, bubble welding, shrinkage cavity compaction and loose compaction can be promoted in the as-cast structure to become a denser structure.

3. Due to the enhanced thermal motion of atoms at high temperature, the diffusion method of atoms and hetero-free diffusion under the action of stress is conducive to the relative reduction of the ingot's chemical composition inhomogeneity.

The above is the introduction of the change of microstructure and performance of 7075 aluminum plate in the process of thermal deformation. If you need to consult 7075 aluminum plate, please contact us.