7075 aluminum plate is our common aircraft aluminum plate, mainly used in aircraft, so I do not know how much you know about the relevant parameters of 7075 aluminum plate, 7075 aluminum plate manufacturers will briefly introduce.

7075 aluminum is about twice that of steel linear expansion coefficient of volume shrinkage rate of 6.5% - 6.6%, easy to welding deformation occurs, 7075 aluminum plate is easy to form crystal crack in welding, and heat affected zone of weld metal and the trend of formation of liquefied crack is bigger, and due to internal pressure is too large, brittleness temperature range of hot cracking occur.The main measures to prevent such cracks are to improve the joint design, select reasonable welding parameters and welding sequence, and use the filler material suitable for the substrate characteristics.

The brinell hardness of 7075 aluminum plate is a relatively accurate and reliable measurement method, but it is usually only applicable to the testing of metal materials whose brinell hardness is below 450 MPa.When testing steel tubes, the hardness d of the test material is usually expressed by the diameter d of the indentation, which is very intuitive and convenient.Vickers Hardness (HV) is used to measure the surface hardness of very thin metal materials and can be tested in the range of 5 to 1000.It combines the main advantages of brucellian and Rockwell methods and overcomes their general disadvantages.But the practice is not as convenient as the Rockwell method.

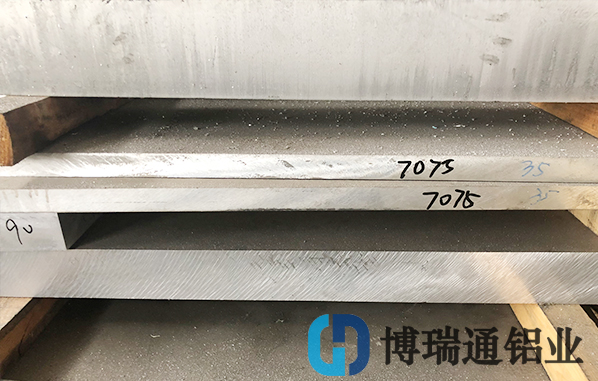

In addition to remind everyone, in the purchase of 7075 aluminum plate to pay attention to the brightness of the surface, and check whether the thickness of veneer uniform.Press the plate with your hand to feel its elasticity and resistance.Its main function is to condense the water in the hot air on the heat exchange plate and to spread and flow down easily.

The above is related to the introduction of 7075 aluminum plate parameters, if you want to know the price of 7075 aluminum plate, you can consult us.