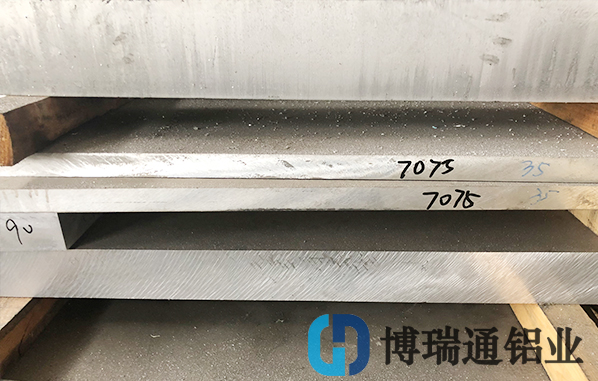

7075 aluminum plate in the use of the need for cutting, the cutting may be because of the way of cutting or improper operation may affect the quality of 7075 aluminum plate, then 7075 aluminum plate manufacturers to introduce to you, the impact of 7075 aluminum plate cutting quality factors.

1. The roughness of the cut surface will affect the quality of the cut surface

There is a direct connection between the cut section grain and roughness. The poor cutting performance of the cut section grain also directly leads to higher roughness, which not only affects the appearance of the edge, but also affects the friction characteristics. In most cases, roughness should be reduced as far as possible, so the sher the grain, the higher the cutting quality.

2. Narrow slit width, which is mainly related to the laser beam spot diameter

When forming the contour inside the parts, the cutting width will affect the quality of the aluminum plate. The main reason is that the cutting width determines the inner longitude of the contour. When the thickness of 7075 aluminum plate increases, the cutting width also increases.

3. Smooth cutting without stripes and brittle fracture

When cutting 7075 aluminum plate thick plate, the molten metal will spurt out behind the laser beam to form curved lines at the cutting edge. The lines closely follow the moving laser beam. In order to correct this problem, reducing the feed rate at the end of the cutting process can greatly reduce the line formation of the lines.

The factors affecting the cutting quality of 7075 aluminum plate are introduced here. If you need 7075 aluminum plate, please contact us.