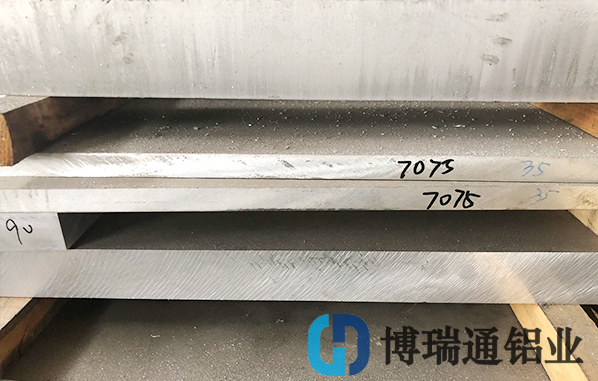

7075 aluminum plate mainly used for aerospace materials, the performance of high strength and high hardness can also be used in mechanical processing, the higher requirements for the mechanical shell can also adopts 7075 aluminum plate, aluminum shell in 7075 May need to slow down when processing, the next 7075 aluminum plate manufacturers will reveal to you, the reason of reduction in 7075 aluminum shell processing.

The processing of 7075 aluminum plate shell is a variety of shell made of 7075 aluminum plate as the raw material. Due to the convenience of production and processing, high coordination ability and high level, it can reasonably enhance the added value, which is enough to be widely used in the electronics industry.

7075 aluminum shell treatment drop speed is not the same as the oil level is more extensive conditions, and the more serious oil spill is not only caused by low or broken oil accidents, resulting in hazards from ongoing manufacturing journal joints;At each stage of the drive gear tooth mating the friction thermal seal reducer will be heard.The higher the running time of the machine, the higher the temperature in the reducer main box, and the volume in the reduction box will not change, so the environmental pressure in the reduction box increases, causing the grease in the reduction box to be sprayed in the reduction box cavity by the snburglar.In order to avoid this situation, we need to adopt deceleration processing in the processing of 7075 aluminum plate shell.

The above is the introduction of the reason for deceleration in the processing of 7075 aluminum plate shell. If 7075 aluminum plate is needed, please consult us.