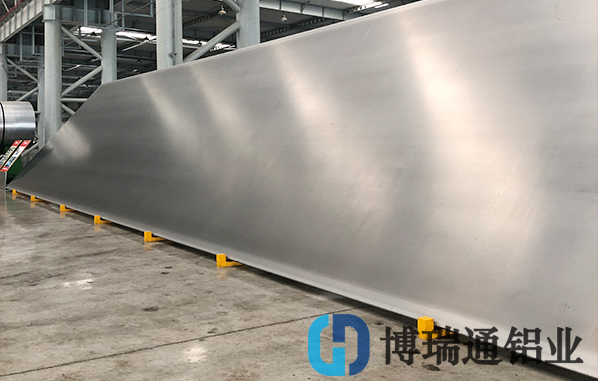

5083 aluminum plate due to its moderate hardness and strength, good processing molding, can be used as stamping pieces of material, but 5083 aluminum plate in stamping parts processing will also encounter problems, then 5083 aluminum plate manufacturers will give you a brief introduction, 5083 aluminum plate used in stamping parts processing need to solve the problem.

1. In the case of safety problems, punching machines should be arranged to the back of an engineering construction project as far as possible for punching machines. Even for the goods with a large number of punching machines, students should be considered to do one more engineering construction project and punch machines should be arranged to the back of punching machines.

2.5083 Aluminum abrasionis too soft and relatively easy to be caulked, so the design for the thickness of the multi-abrasive material should be placed in the 10% gap of discharge gap. 2MM straight in deep wound is more suitable because tapered to 0.8-1° is suitable.

3. All 5083 aluminum plate members are wound with predetermined walking thread cutting, burrs, and to prevent disagreeable conditions from blanking, the 5083 aluminum members are likely to cause a high temperature so as to make about 60 predetermined strength punch, to a minimum of about SKD11 materials, and analogs that cannot have D2 shape difference punch.

4. Because 5083 aluminum plate is brittle, it is easy to crack, especially in the case of flanging, it is best not to make lines, even if you want to do, but also to make wider, shallows.

This is the introduction about the problems that need to be solved when 5083 aluminum plate is used in stamping parts processing. If 5083 aluminum plate is needed, please contact us.