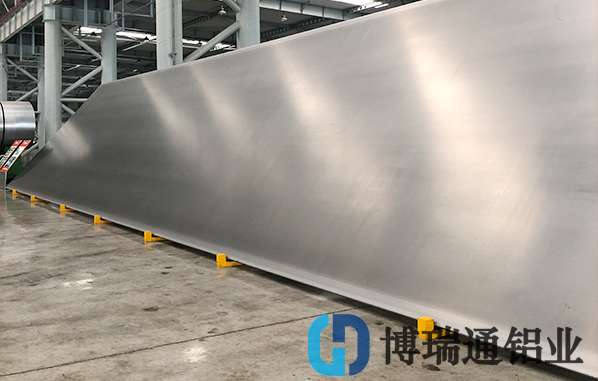

5083 aluminum plate in use before the need to go through surface drying treatment, is generally used to dry processing, next 5083 aluminum plate manufacturers will give you introduce, 5083 aluminum plate surface drying drying treatment method.

Drying method is commonly used in surface treatment of 5083 aluminum plate.According to the different baking temperature can be divided into low temperature drying, medium temperature drying and high temperature drying.

1. Low-temperature drying. Low-temperature drying refers to the drying method. When the baking temperature is lower than 100 degrees, low-temperature drying is mainly used to dry the anodized aluminum plate 5083, and the general anodized sulfate temperature should be 80℃ or lower.The drying of 5083 aluminum plate after anodic oxidation should also be controlled within 100℃.

2, drying temperature, drying temperature drying refers to the temperature in the method of 100 ~ 150℃ drying method is suitable for the anodized drying treatment.

3. High-temperature drying is a high-temperature drying when the temperature is above 150℃, and the drying temperature is controlled at 180 ~ 200℃. High-temperature drying is only selected when electrophoresis paint is used.

The drying method of 5083 aluminum plate surface drying is introduced here, if you need 5083 aluminum plate can contact us.