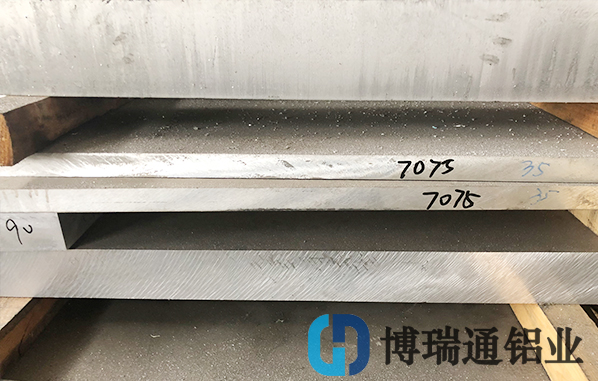

As we all know, car lightening is the current development trend. The 7075 aluminum plate can be used as wheel hub in the car. There are two technologies for the production of 7075 aluminum plate wheel hub.

The traditional casting and forging technologies are mainly used in the production of 7075 aluminum plate wheel hub.

casting

It is economical to cast at low pressure, by casting molten metal into a mold to form and harden.Strong vacuum is used to suck the metal into the mold, which is helpful for the enterprise to keep constant temperature and remove impurities. There is no porosity formed in the casting, and it has uniform density distribution and high strength requirement.The aluminum wheel produced by high reverse die casting (HCM) process is almost identical to the aluminum wheel produced by forging.

forging

Forging is an advanced method of manufacturing 7075 aluminum plate wheel hubs.Rolling forging is a form of forging in which pushing the blank out of the hub can greatly reduce the thickness while maintaining sufficient strength.Forged 7075 aluminum plate hub not only has uniform density, smooth surface, thin ring wall, light weight, but also can withstand greater pressure.

The two technologies of producing 7075 aluminum plate hub are introduced here. If you need to consult the price of 7075 aluminum plate, please contact us.