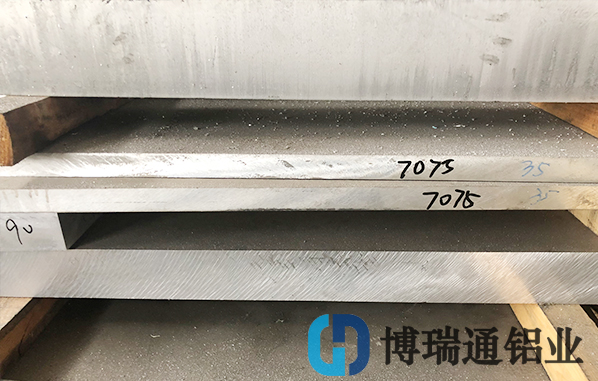

7075 aluminum plate after the production, as 7075 aluminum plate manufacturers may find in the surface of the aluminum plate folding, bubbles and other problems, then what is the main cause?How do we avoid it?Let me tell you a little bit about it.

1. There is compression folding between 7075 aluminum plates, and the main reason for the problem may be as follows: the bearing of the calender generates heat, which makes both ends of the roll swell, resulting in the 7075 aluminum plate being thin as the center;Before pressing, 7075 aluminum plate is affected too much by waves, so that the pressing capacity is too large, and then the pressing can be folded;When the thin plate is pressed into the wrong society people are easy to lead to the occurrence of bending;Plate thickness difference at both ends is large, easy to fold.

2. Appearance bubbles: The main reason for the problem may be that the uneven surface of the ingot is dirty to the east, and the ingot is not cleaned in time before the furnace is installed, or the cast block and the 7075 aluminum plate have the traces of corrosion and washing on the surface;Another is that the casting surface can be oxidized by heating and working time cannot be too long or the temperature requirement is too high.

3. Cracking of the casting block: During hot rolling, the pressure down work is too large, cracking from the processing of the ingot end may be caused by too high or too low temperature requirements of the casting heating system.

The above is the reason for the appearance problems of 7075 aluminum plate, I hope you can sum up the reasons to avoid the above situation. If you need to know the price of 7075 aluminum plate, you can consult us.