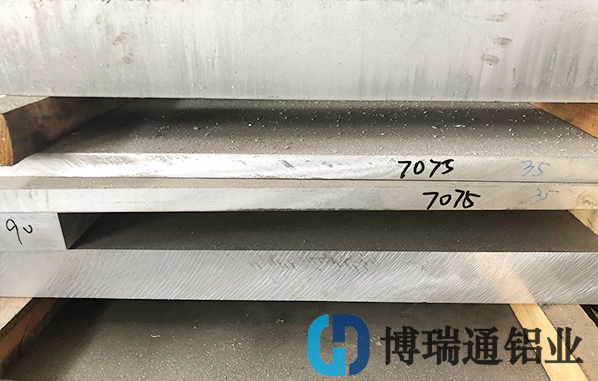

7075 aluminum plate before use is the need for surface treatment, today 7075 aluminum plate manufacturer to introduce to you, 7075 aluminum plate anodized surface treatment matters needing attention.

1, the anodic oxidation temperature is generally lower than 23℃, the temperature is too high, so the cold sealing agent consumption is great, the surface is yellow.

2, anodizing technology should be immediately after the problem of water cleaning, if not cleaning, easy to cause liquid channeling environmental pollution, increase the fluorine consumption of the sealed tank.

3. The impurities in the sealing groove should be removed, otherwise it will accelerate the pH rise and the consumption of fluorine.

4, with ammonium fluoride injection slurry reinforcement tank, each cubic according to 20T aluminum profile, should be poured a clear bottom.

5, in order to improve the quality of grouting reinforcement and speed up the drying speed, it is strongly recommended that the cold sealing to 55 + 5 ° c for flushing after 10 ー 15 minutes, also known as the cold sealing post-processing technology.

7075 aluminum plate anodized surface treatment matters needing attention are introduced here, if you need to know the price of 7075 aluminum plate, you can contact us.