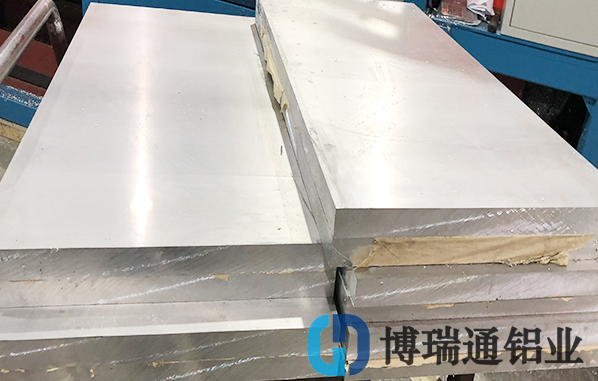

Sometimes 2A12 aluminum plate may need to be treated on the surface before use, and sometimes it will be treated with nickel plating. Next, 2A12 aluminum plate manufacturers will introduce to you the method of electroless nickel plating on 2A12 aluminum plate.

There are two methods of electroless nickel plating: zinc dipping - pre - plating and direct electroless nickel plating.

The disadvantage of the pre-leaching method is that the nickel layer of 2A12 aluminum plate is easy to peel off in the wet corrosive environment, and there is a nitric acid dezincification process between two dips of zinc, which causes pollution to the production environment. Therefore, the development of this technology is restricted to a certain extent.

Direct electroless nickel plating is easy to operate, energy saving, environmental protection, wide range of use and management, uniform coating.Can improve the corrosion resistance and service life of 2A12 aluminum plate products, can improve the wear resistance and lubricity of processing parts and other functions, so it can become a surface processing information technology development trend.

The above is the method of electroless nickel plating on 2A12 aluminum plate. If you need 2A12 aluminum plate, you can contact us.