5052 aluminum plate needs to follow some requirements during blanking. Next, 5052 aluminum plate manufacturers will give you a detailed description of the specific requirements.

Blanking die reasonable clearance: general stamping processing of 5052 aluminum plate thickness within 2mm blanking die clearance value can take less than 10%, if the requirements of small burr, you can take about 5% (bilateral clearance).

When the gap of blanking die is reasonable, the upper and lower cracks of 5052 aluminum plate material can be superimposed on each other in the same position.In this way, the bright zone of the cutting surface is larger, while the collapse surface and burr are smaller and the fracture taper is moderate, and the surface of the parts is relatively smooth.The blanking parts can obtain satisfactory quality.And when the clearance is smaller, the die life is smaller, but the quality of the workpiece is better.When the gap is larger, the service life of the die is larger, but the quality of the workpiece is poorer.

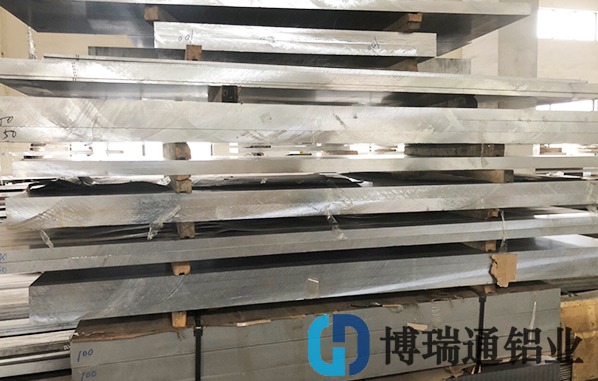

The requirements to be followed in blanking of 5052 aluminum plate are introduced here. You can contact us if you need 5052 aluminum plate.