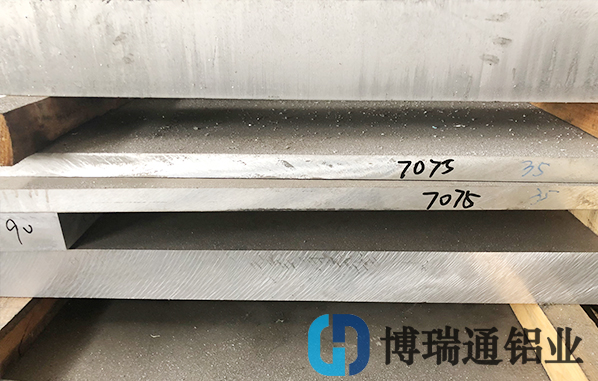

When 7075 aluminum plate is in use, it generally needs to be cut, but in the case of different thickness, there is also a difference in cutting. Next, 7075 aluminum plate manufacturers will introduce the difference of cutting under different thickness of 7075 aluminum plate.

7075 aluminum plate cutting sheet or cutting machine with high reflectivity and high thermal conductivity, thickness of up to 6mm 7075 aluminum plate can be cut.When processing 7075 aluminum plate less than 3mm, because sawdust will paste the saw blade, the effect is not very good, the band saw is also good, through optimization and adjustment can get a better burr-free cut.For thicker 7075 aluminum plates, there will be edge burrs that are difficult to remove.

7075 aluminum plate cutting method: from left to right, from top to bottom, not inverse cutting;When the cutting is finished, check it. According to different materials, there are hard and soft ones. Hard ones don't matter, and soft ones stick to the saw blade.There may be a little flame, but it's hard to extinguish.When nitrogen is used, the cutting surface is smooth.After cutting 7075 aluminum plate, put the plate gently on the cleaning platform to clean, to avoid surface damage of 7075 aluminum plate.

The above is about the difference of cutting under different thickness of 7075 aluminum plate. If you want to know the price of 7075 aluminum plate, you can contact us.