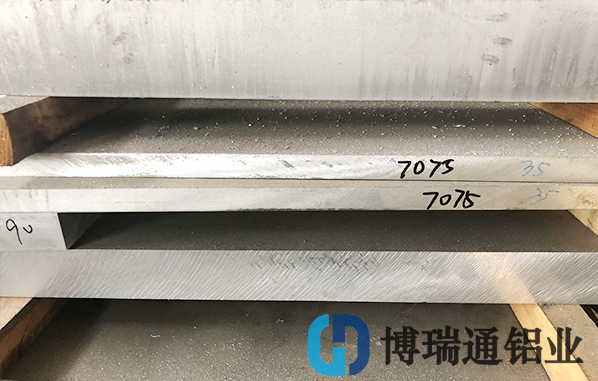

7075 aluminum plate low density, high strength, in aviation, automotive, machinery and other industries have been widely used, but due to its low surface hardness, poor wear resistance, resulting in 7075 aluminum plate material failure, limiting its further application.At present, the solution is to electroless nickel plating, nitriding and thermal diffusion on the surface of 7075 aluminum plate. Next, 7075 aluminum plate manufacturers will introduce the role of electroless nickel plating on 7075 aluminum plate.

Electroless nickel plating can form a layer of nickel plating on the surface of 7075 aluminum alloy, and with the increase of plating time, the thickness of the nickel plating layer thickened.Ni4N and other nitrides can be formed on the surface of 7075 aluminum alloy with nickel layer by gas nitriding.In the process of gas nitriding, Al atoms and Ni in the matrix are mutually diffused to form A13Ni and A13N2 compounds. With the prolonging of nitriding time, the number of Ni4N, A13Ni and A13N2 compounds increases.The presence of these compounds increases the surface hardness of the aluminum alloy, up to 700HV, which is 7-8 times the hardness of the matrix.After annealing at 460℃ for 10min, the diffusion layer of Al-Mg-Zn alloy phase with different compositions is formed in the diffusion zone. The hardness of the diffusion layer is up to 240HV, which is 3 times that of the Al alloy matrix.After annealing at 470℃ for 60min, the microstructure of the diffusion layer is the eutectic structure of A1-Mg-Zn and the Al-Mg-Zn phase with high Zn content. The microhardness of the diffusion layer is 77.2HV, which is 20HV higher than that of the Al alloy matrix.

7075 aluminum plate electroless nickel plating effect of this, want to consult the price of 7075 aluminum plate can contact us.