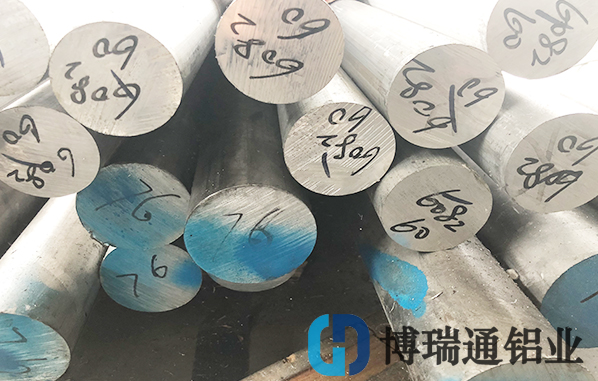

During the production of the 6082 aluminum bar, the problem of black dragging or slag clamping may occur. What should we pay attention to in order to reduce the black dragging and slag clamping of the 6082 aluminum bar?Next 6082 aluminum bar manufacturers to give you advice.

1. First of all, after cutting the 6082 aluminum bar, the surface impurities should be blown clean with the air duct. The main purpose is to reduce the amount of coal ash brought in and reduce the source of black dragging and slag inclusion;

2, to leave enough pressure residual thickness, too thin pressure residual will lead 6082 aluminum bar dead zone involved in the end of the profile, resulting in black drag, slag;

3. Control the extrusion speed. In order to prevent turbulence from being involved in epidermal impurities, decelerate the ends.

4, every change of mold need to clear the cylinder.

The above are related methods to reduce the black dragging and slag inclusion of 6082 aluminum bar. If you need to know the price of 6082 aluminum bar, please consult us.