We all know that in the purchase of 5083 aluminum plate, some customers are very precise requirements for the size, then we are in the 5083 aluminum plate cutting how to grasp the accuracy is very important thing, the next small series will give you an introduction, to improve the 5083 aluminum plate longitudinal cutting precision method.

Disc cutter diameter and thickness: the diameter of the disc cutter determines the shear Angle.When the outside diameter is large, the shear Angle is small, the motor power is also smaller, more energy saving.If the diameter is too large, the rigidity of the disc knife will be weakened and the service life of the blade will be shortened.The strength of the cutter plate is determined by the thickness of the disc cutter, but the cutter plate is not the thicker the better, too thick is difficult to operate, and the price is high, the thickness of the cutter plate is also limited.In addition, the cutter head should not be too thin, because the gap of the cutter head will change in the shearing process.It changes the shape of the cut.The machining accuracy and hardness of disc cutter play an important role in its service life.According to the practical experience, the thickness accuracy of the disc cutter is 0.005mm, the flatness accuracy is 0.025mm, and the parallelism accuracy on both sides is 0.005mm. When using the disc cutter, the edge will be worn and passivated due to the long time pressed on the sheet, and the metal fatigue layer will appear in the cutting part.In order to ensure the shear quality, it is necessary to wear the cutter disc.

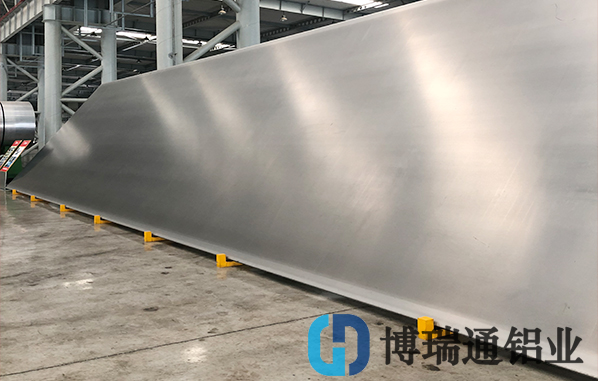

The above is the method to improve the longitudinal cutting accuracy of 5083 aluminum plate. If you need 5083 aluminum plate, please contact us.