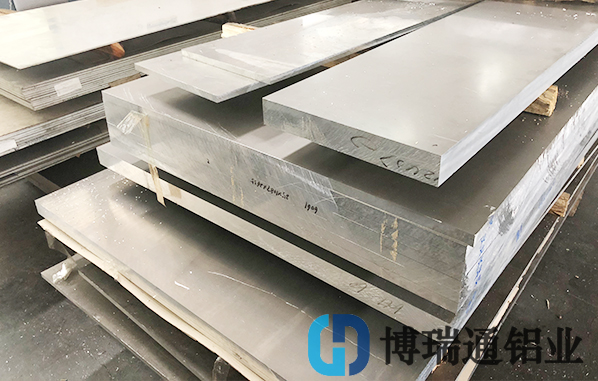

6061 aluminum plate is a common machining material, currently widely used in mechanical processing, that in the processing of 6061 aluminum plate need to pay attention to some problems, the next small series to give you a specific introduction.

1. Generally speaking, it is recommended to punch holes at the back of the project. For 6061 aluminum plate products with a large number of holes, one more project can be considered.

2. When designing the mold, the gap should be filled with bilateral material thickness of 10%, the straight depth of the cutting edge should be 2MM, and the taper should be 0.8-1°.

3, 6061 aluminum plate in the bending is easy to produce aluminum chips, will cause spot damage, indentation, 6061 aluminum plate needs to be affixed with PE film, in the case of rollers and electroplating, forming block is recommended to be polished and plated with hard chromium.

4, 6061 aluminum plate is used for walking thread cutting all the requirements, blanking and not smooth, to prevent the phenomenon of burr, 6061 aluminum plate products in high temperature, so in the punch hardness more than 60°, and the above materials SKD11, D2 and at least like the shape of the press is not poor.

Some problems need to be paid attention to when processing 6061 aluminum plate are introduced here, if you need 6061 aluminum plate, you can consult us.