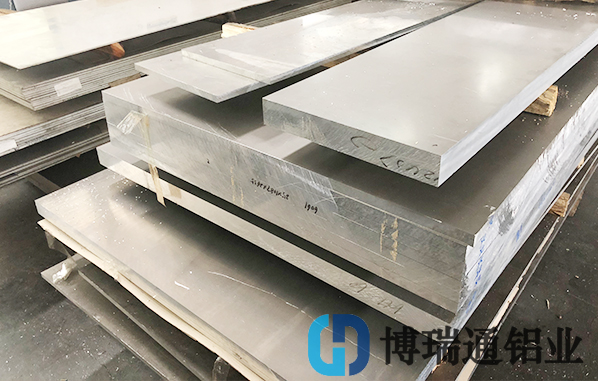

6061 aluminum profiles may produce scratches on the surface when pressed. What measures should we take to avoid scratches in this case?Next 6061 aluminum plate manufacturers to introduce to you, to solve the 6061 aluminum plate profile stamping scratches method.

1. Improve ingot quality

In the casting process, the larger slag particles are filtered out to improve the purity of liquid aluminum, which can greatly reduce the scratch of 6061 aluminum profile.

2. Improve the quality of mold repair

Percussion should be avoided because at room temperature the hardness of the finished mold is high, it will knock the dark crack, once pressed damaged, this can easily hang in the residual mold to seal holes and scratch the tape work.

3. Improve mold manufacturing quality

The design of die structure is different, designers should be reasonable when distributing die, to avoid the occurrence of large local uneven flow rate in the extrusion process.

4. Improve the production process

The immersion ingots should be used to reduce the extrusion temperature, which can reduce the pressure, increase the die stress conditions, indirectly improve the strength of the die;At the same time, the reduction can extrude 6061 aluminum metal flow is relatively uniform to avoid slagging, thus reducing the drawing.

5. Adopt scientific and reasonable operation management method: when 6061 aluminum plate is scratched, stop immediately. After stopping, return the extrusion shaft and use the reverse extrusion cylinder to pull out the residual aluminum in the mold.If the slag is severe, the metal in the guide hole can be quickly removed, and then the squeeze tube can be closed again and locked to resume the squeeze.

The method to solve the stamping scratch of 6061 aluminum plate profile is introduced here, if you need 6061 aluminum plate, you can consult us.