When 5052 aluminum plate is used as decorative material, the surface quality requirements are higher, if the surface of 5052 aluminum plate scratches, it must find out the reason and solve, next 5052 aluminum plate manufacturers to introduce several possible causes of 5052 aluminum plate surface scratches.

There are a certain number of hard metal particles in the 5052 aluminum plate. When the metal flows through the working belt during the extrusion process, these segregation surfacing substances or hard metal particles attach to the surface of the working belt or cause damage to the working belt, and eventually scratch the surface of the 5052 aluminum plate.

There are sundry materials on the mold, and the hardness of the mold is low. As a result, the surface of 5052 aluminum plate is injured and scratched during extrusion, leading to the profile;

The discharge bed track or pendulum has a bare metal or graphite strip with a hard inclusion in it when it is in contact with the aluminum plate 5052 causing scratches on the surface profile;

5, 052 aluminum plate was scraped by manually dragging on the swing bed;

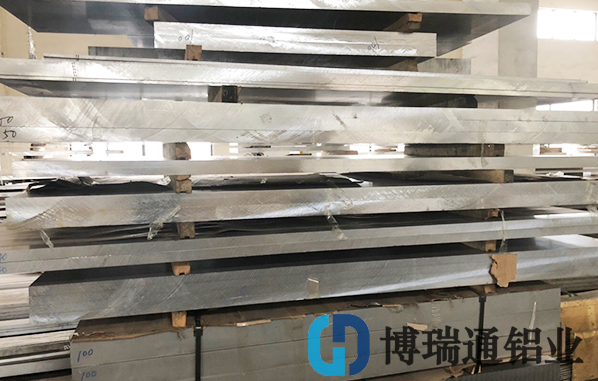

Damage may be caused in transit.In addition, if the 5052 aluminum sheet is not packaged well, its surface will also be damaged.

The reason for the surface scratch of 5052 aluminum plate is introduced here. I hope you can avoid the above reasons and produce a good quality 5052 aluminum plate. If you need 5052 aluminum plate, please contact us.