I do not know if you have found that sometimes the surface of 5083 aluminum oxide film color is not uniform, leading to its color is not uniform there are many reasons, but how to control the 5083 aluminum oxide film color uniformity?Next 5083 aluminum plate manufacturers to introduce to you, control the 5083 aluminum plate oxide film color uniformity of the key factors.

The reason why it is difficult to obtain a conductive oxide film after alkali corrosion of 5083 aluminum plate workpiece can be eliminated after many factors affecting the development and formation of conductive oxide film can be eliminated. Considering whether there is a problem of excessive aluminum ions in the alkali corrosion solution, the alkali corrosion solution is very thick, but the corrosion rate does not increase fast.It is recommended to replace the alkaline solution, alkaline solution, because after long-term use will accumulate excess aluminum ions, aluminum ions are difficult to dissolve on the surface of the aluminum 5083, thus affecting the surface of the conductive contact of the aluminum 5083 oxidation of the aluminum solution with the oxide film formed.In addition, by changing alkali corrosion solution, 5083 aluminum plate after alkali corrosion can be rinsed in hot water and then put into flowing water for rinsing. Then, after sufficient rinsing, conductive oxidation technology treatment can be analyzed.Quickly leave hot washing in hot water and immediately immerse in water to prevent the drying of the workpiece through the oxide film forming on the 5083 aluminum sheet affected by the formation of conductive oxide film.

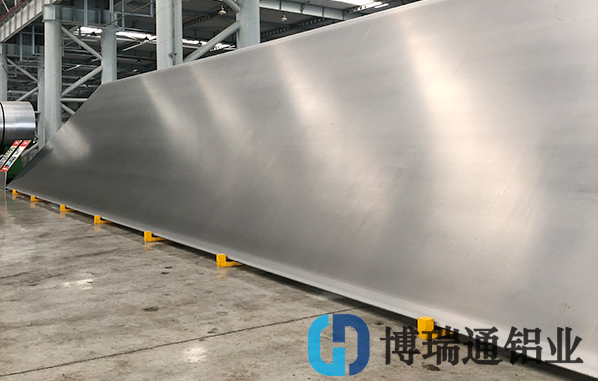

The above is the key factor to control the uniform color of the oxide film of 5083 aluminum plate. If you need 5083 aluminum plate, please consult us.